Triertech T8800 an excellent double-sided final inspection AOI, the industry's exclusive AI appearance inspection function accurately captures defects

-Double-sided 2D final inspection AOI

-The industry's exclusive AI appearance inspection function can detect all kinds of complex appearance defects and replace the manual final inspection

-The two cameras move synchronously, and the asynchronous interlock takes the image to avoid the interference of the upper and lower light sources

-With the accumulation of defect data, the iterative accuracy of AI algorithm model is gradually improved

-The powerful SPC software provides rich and accurate data statistics

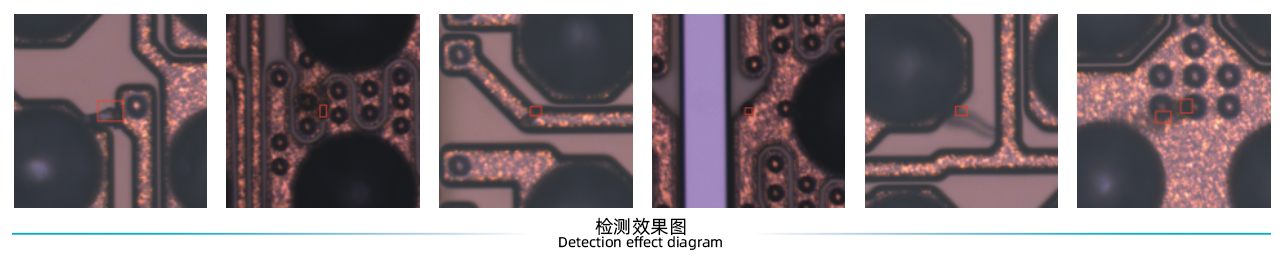

Flexible positioning algorithm compatible with products featuring varying backgrounds and chromatic aberrations.

High-precision defect detection algorithms including image enhancement, edge detection, and template matching, capable of accurately identifying microscopic defects such as cracks, scratches, foreign matter, and solder joint defects.

(1)Image enhancement: Improves image quality through contrast adjustment to enhance defect visibility

(2)Edge detection: Precisely identifies wafer surface edge features using algorithms like Canny edge detection

(3)Template matching: Rapidly identifies non-compliant areas through comparative learning with standard templates

High-precision measurement algorithms incorporating feature extraction, utilizing boundary tracking algorithms to extract object contour information for accurately measuring dimensions of features like contact holes, conductor line widths, and spacing.