The equipment is applicable for post-packaging inspection of die surface defects after Die Bond and Wire Bond processes in semiconductor back-end assembly, as well as solder joint and gold wire defect inspection after gold wire bonding.

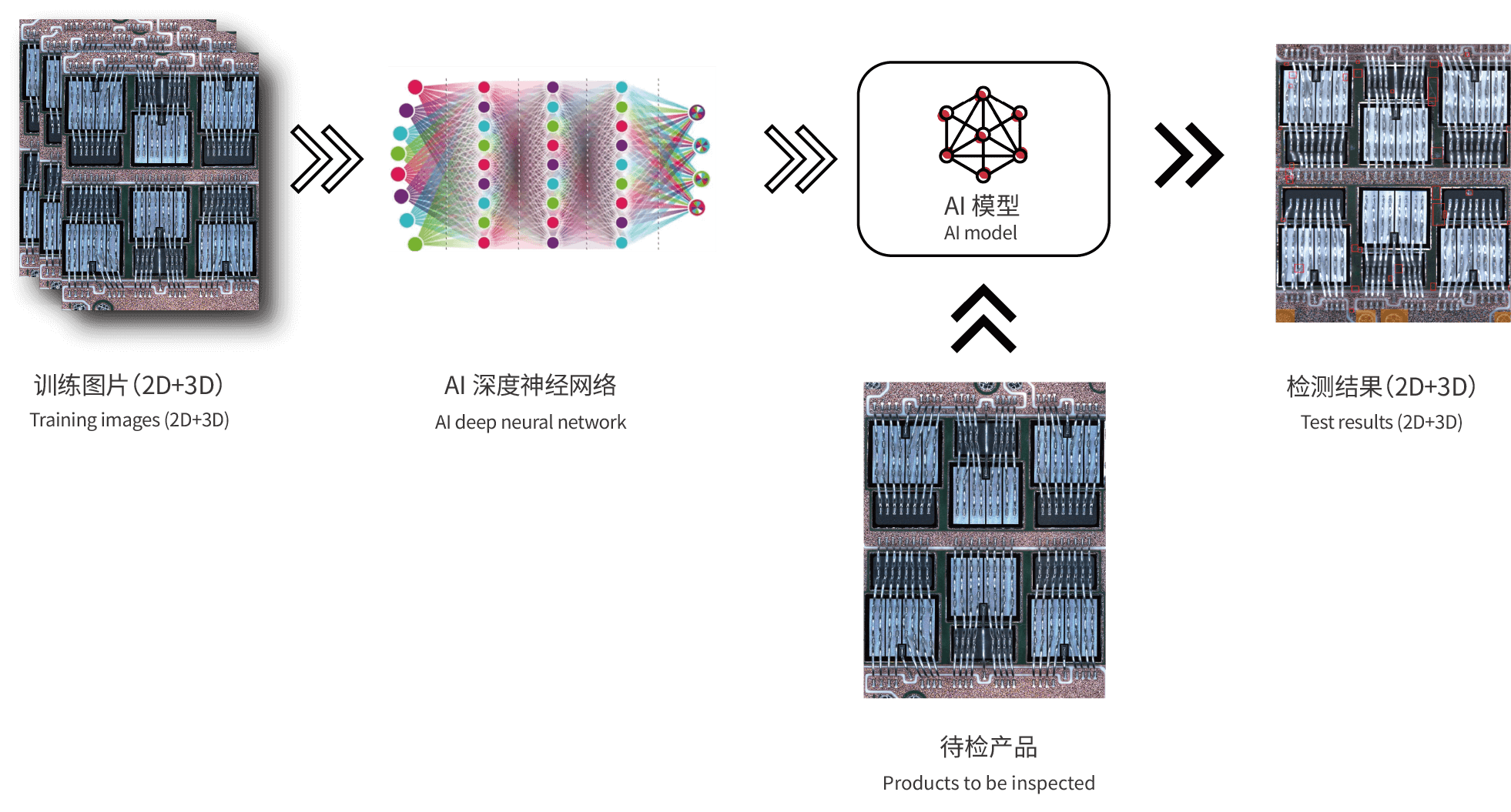

Deep learning AI algorithm

Deep learning algorithms enable neural networks to automatically learn features and extract information from massive data through training, performing intelligent analysis on image or video data. The current software integrates five universal algorithms based on CNN and Transformer architectures: classification, segmentation, object detection, character recognition, and unsupervised learning (good product learning). These algorithms demonstrate significant effectiveness in practical applications such as defect recognition in complex environments, component classification, and character reading scenarios. With deeper research, we have not only refined existing model architectures to reduce parameter quantities but also leveraged NVIDIA's efficient deep learning inference engines to implement computational graph optimization, accuracy improvement, layer simplification, multithreading, and batch inference processing. These enhancements have substantially improved model inference speed and efficiency.

· Multi-focus fusion technology stably reconstructs 0.6 mil gold wire 3D topography

· Equipped with 65MP high-speed camera achieving 1.6μm pixel resolution

· Industry-leading AI 2.0 detection algorithms

· User-friendly software with integrated auto-programming functionality

· Camera configuration: 65MP

· Lighting configuration: RGBW four-color LED multi-angle lighting system (standard coaxial lighting included)

· Resolution: 3.2μm

· Detection accuracy: 10μm

· Defect detection rate: ≥99%

· Detection accuracy rate: ≥95%

· Detection repeatability: ≥95%

· Detectable defects: Wire contact, wire sagging, wire sweep, wire breakage, missing solder joints, redundant solder joints, bond wire height, wire-to-wire spacing, contamination, scratches, foreign material deviation, corner defects, warpage, presence/absence verification, misplaced dies, edge chipping, corner chipping, overfill, underfill, encapsulant bleed height...

· Equipment uptime: 24 hours